While in operation process pipelines, vessels, tanks, equipment, building structures are prone to corrosion which in combination with wear (erosion) leads to decrease of wall thickness and consequently to accidents.

Renders services for detection of corrosion, depth of external and internal corrosion damages:

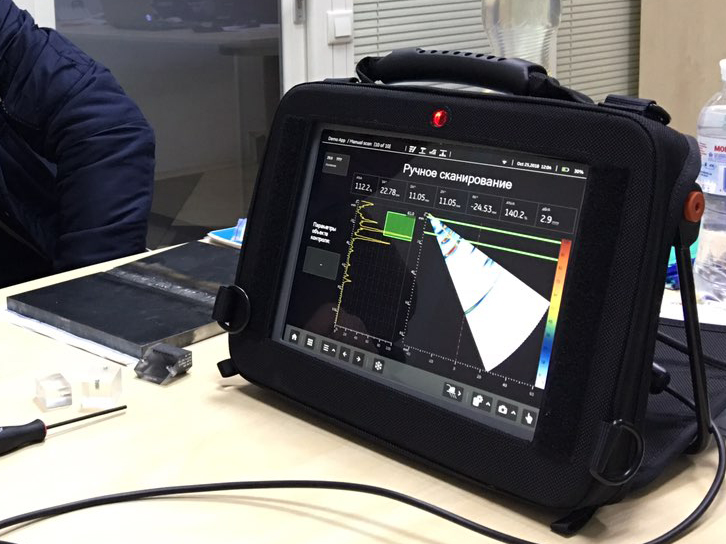

“Center of industrial diagnostics and control” LLC renders services for detection of corrosion, depth of external and internal corrosion damages of base metal and determination of its actual thickness along the whole length of examined material. Works are conducted using ultrasonic phased array flaw detector Mentor UT 32/32 (General Electric). This device is optimized for corrosion monitoring and provides the highest level of quality and accuracy of measurements with resolving power by thickness up to 0,05 mm. Besides the device can stand up to tough environment of field usage with an IP65 durability rating.

The detector utilizes Mentor Create software that enables creation of digital flow sheets of ultrasonic examination and their transmission as slides into Microsoft Power Point. Also this application includes all the necessary multimedia content (photo, video, PDF files etc.) and allows generating step-by-step pages for execution of the whole flow sheet and transferring it via local network or Internet to any gadget for analysis.

Mentor UT allows to save А-scan data and process control results and reports immediately on the device.

At final stage of diagnostics, specialists of the company can perform additional laboratory examinations of content and structure of metal in locations of corrosion defects and provide recommendations regarding repair or replacement of damaged sections.